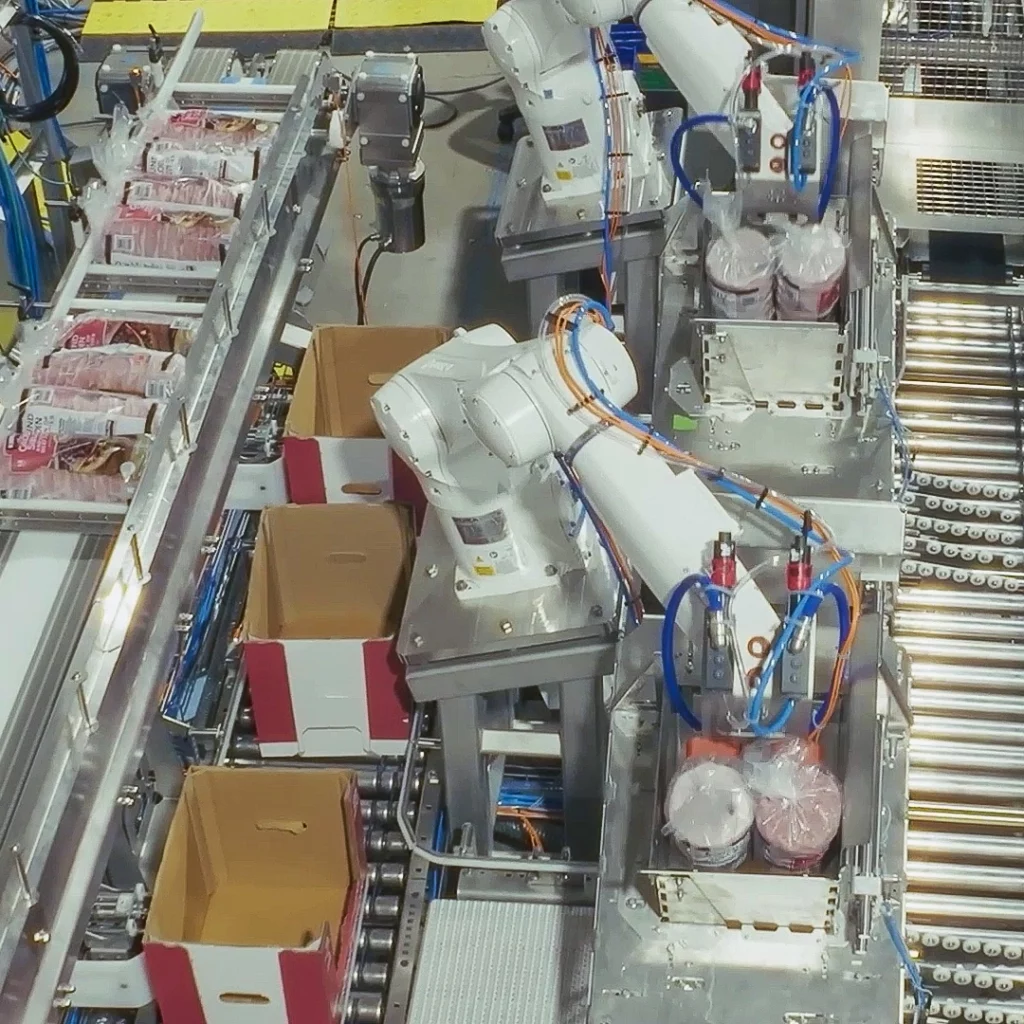

Case Packing

Manually packed cases increase the risk of contamination and slow production, costing manufacturers billions annually in recalls and costing manufacturers billions annually in recalls and downtime.

Washdown automation reduces cross-contamination risks by 80%, delivering the speed and hygiene manual labor can’t match. Axinova’s case packing cells get your products into the box. Pre-engineered functional packages include high speed delta robots, scara robots, and 6 axis arms allow for a high variety of packaging formats, sanitary environments, and footprint options.

See Our Case Packer in Action

Your Satisfaction is Our Top Priority

Washdown Hygiene,

No Compromise

Food safety is non-negotiable in food production. Manual packing is a risk.

We offer:

• Full washdown-rated construction

• Stainless steel, proprietary frames built for high-pressure environments

• Minimal horizontal surfaces to prevent residue build up

• Built for easy cleaning and reduced contamination risk

High-Performance, Reliable Automation

Consistent packing at the speed your line demands.

• Precise, repeatable robotic case packing for

RSC and display-ready formats

• Vertical pack capability for stacked or upright

presentations

• Runs 24/7 with minimal human intervention

Tailored Integration for Any Plant

No two production lines are the same, that’s why we don’t offer one-size-fits-all.

• Fully customizable layouts designed to fit your

footprint and flow

• Seamless integration with upstream

conveyors and downstream equipment

• Designed for fast SKU transitions with minimal

downtime

• Scalable systems that grow with your needs

Ready to Streamline your Process?

Let’s discuss how we can simplify and optimize your production, together.